Less than a year ago, HPE announced a new set of products under its EdgeLine banner. These devices were created to enable the Internet of Things (IoT) to connect with other IT infrastructure and to allow IT to tap into sensor data and other capabilities directly attached to devices. With the term, Internet of Things, visions of connected refrigerators and connected toaster ovens spring to mind, but when it comes to the Enterprise, where the new HPE is clearly focused, what does an IoT play look like?

HPE believes that when it comes to IoT in the enterprise, it is all about empowering processing and analytics to occur close to where the data is being generated. This past week at HPE Discover in Las Vegas, HPE announced the EdgeLine 1000 and EdgeLine 4000 series of devices that allow more processing power to be deployed into the field near these connected devices that generate data. These devices join the EdgeLine EL10 and EL20 gateway devices it introduced in December at HPE Discover in London. The idea is that by processing the data in the field, the enterprise can save on data transmission, security and can really do some interesting new things in the field. HPE sees this as critical in the success of IoT for enterprise.

The EdgeLine 1000 uses a single ProLiant cartridge (the kind used in HPE Moonshot) in a ruggedized metal case with built-in expansion slots for drives and PCI cards. The EdgeLine 1000 shown off at HPE Discover also featured integrated wireless networking on the system. The EdgeLine 4000 accommodates up to 4 ProLiant cartridges and resembles a traditional rack-mount server.

Why Process Near the Data?

Many of these industrial uses of IoT may be in remote and disconnected parts of the world. It may not be feasible or cost-effective to pay for the data plans required to connect these devices and push all of that data to a datacenter or the cloud. Remote oil platforms, refineries, industrial sites, and even remote jungle deployments [like the one HP showcased with Conservation International] may not have available connectivity options. Or if they do, satellite internet connections are metered and expensive. And even in well connected areas, it may come down to security and not wanting these devices actually talking to the Internet. There may be regulations or laws that govern what connectivity can be established – or it may be simple corporate secrets where they do not want to introduce the risk of transmitting the data outside of its corporate IT.

While at HPE Discover, the team from DS Virgin Formula E racing talked with our group of bloggers. One of the most interesting things about Formula E racing is the amount of sensor data created by the electric race cars and then the amount of data analytics that the teams are performing on that data in the field. For the DS Virgin Formula E team, this was a huge contributor to a much more successful season in year 2. During the first year, the team did not have analytics in the field and were purely racing based on instinct and some review of the sensor data manually. Now the team has deployed HPE Moonshot in the pit and they can download and analyze the sensor data received from the car. In a typical race day, the team comes to a track, has no previous experience with the track, and after a couple rounds of qualifying with short times in between, they run the final race. By using analytics, they take the data obtained by the car in qualifying and they can make adjustments and plans about how to run the race best and most efficiently. The results show for themselves with the team taking the poll in most of the races this season and ranking currently 3rd in the entire field for the year. Taking the same data and sending to to the cloud is a waste of time – the transmission time is better spent doing analytics during very tight turn-arounds. The same principal applies with IoT data.

You also have to determine what data is actually valuable. Everyone talks about the astronomical size of the data that will be generated from IoT devices. Even if you have good connectivity, using all of your available upstream bandwidth to transmit sensor data is probably not the best use case of your connectivity. Case in point, I personally started with a DropCam at home for security reasons – but I dislike the device because it clogs my upstream – constantly transmitting video the cloud. Instead, I have setup another set of cameras that only transmit minute long clips when a camera detects motion. That’s really what I care about – knowing that something moved and seeing video of that – not broadcasting 24/7. IoT generated data is a lot the same and this is where HPE’s vision lies – putting the software to detect the motion or a failure or other event near the data generating device and then allow the detection to occur there.

Unlocking New Capabilities

Also by having processing available in the field, you open up new capabilities to remote workers. HPE was demoing a pump system from FlowServe on the show floor at HPE Discover. FlowServe makes industrial pumps for major operations around the world. Approximately 10,000 of those pumps are outfitted with sensors that can communicate problems, status and operational data points. FlowServe has been working with HPE and the EdgeLine product line to take their sensor-enabled pumps and extend those capabilities by connecting them.

In the demo I saw, FlowServe was able to connect the pump system to an EdgeLine 1000 system and then run real time monitoring of the pump. With these located thousands of miles away from main office locations, this sensor data could enable operators to know when conditions that may ruin a pump occur and shutdown the system to prevent problems. Now, that’s not new – what is new about the solution is that the EdgeLine system could then transmit that problem to a help desk and arrange for a repair automatically. That’s the power of connectivity.

In the demo I saw, FlowServe was able to connect the pump system to an EdgeLine 1000 system and then run real time monitoring of the pump. With these located thousands of miles away from main office locations, this sensor data could enable operators to know when conditions that may ruin a pump occur and shutdown the system to prevent problems. Now, that’s not new – what is new about the solution is that the EdgeLine system could then transmit that problem to a help desk and arrange for a repair automatically. That’s the power of connectivity.

Once a repairman is onsite, however, he may have never seen the installation and may not know anything about where the actual problem occurred. HPE and FlowServe were showing off an augmented reality program that paired an iPad with special software that take a live picture of the installation and overlays sensors and status to the live picture. This augmented reality app can show the repairman where the problem has occurred, give them important data about what needs to be services and even allow the repairman to start the system back up and ensure that his repair was successful by communicating security with the EdgeLine system in the field. A photo of the augmented reality app is to the right.

Smart Cities

HPE was talking specifically about industrial applications – manufacturing, oil, gas – but an interesting fourth example – smart cities. In the case of smart cities, HPE is thinking about traffic cameras, environmental sensors and other applications of technology to connected devices. In its concept of smart cities, HPE showed demos of connect vehicles communicating with one another or with drivers to warn about potholes or other obstructions in the roadway – sort of like Waze, but with much more automation and precision. Booths also showed off solutions for smart parking, health care, supply chain, waste management, the connected car and personal safety tracking devices. All of the solutions were built around interactions that we would have with technology to assist us in our daily lives.

I also talked with a security researcher in Hewlett Packard Labs and we had an interesting discussion about pushing facial recognition analytics out to individual cameras where specific persons of interest could be recognized by the camera, rather than having to transmit all the video data back for centralized analytics to run on it. Innovation like that could enable quicker arrests and pinpointing terrorists before they strike.

While I walked around the booths demoing concepts for the smart city, I have to admit that I thought about TomorrowLand and Walt Disney. This had to be sort of how TomorrowLand felt when it first debuted. Very futuristic concepts of how a smart city could run.

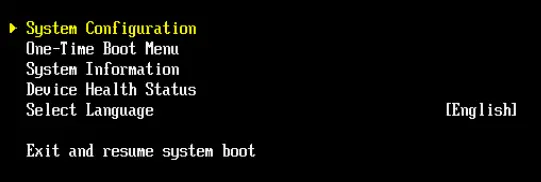

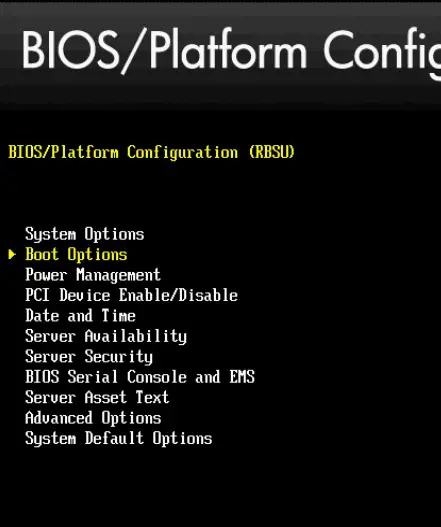

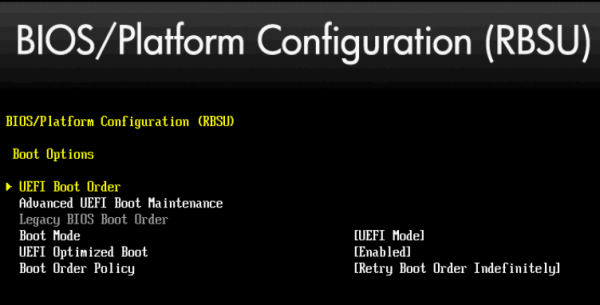

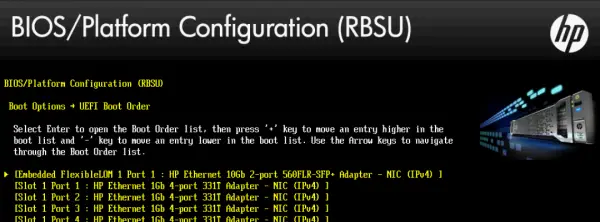

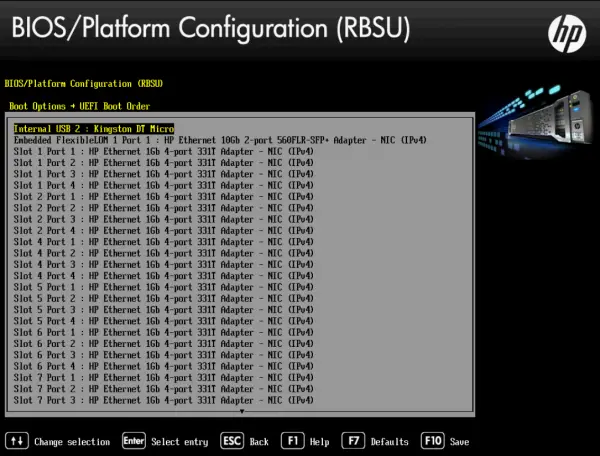

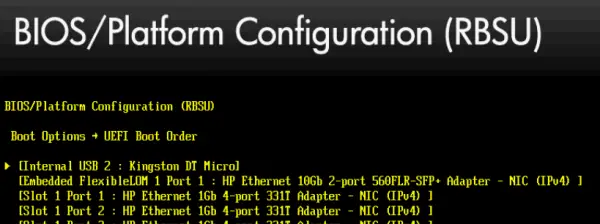

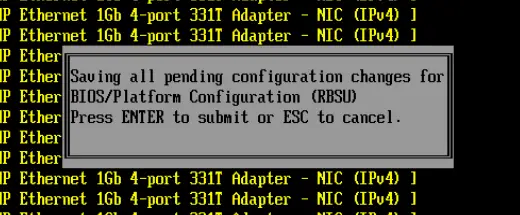

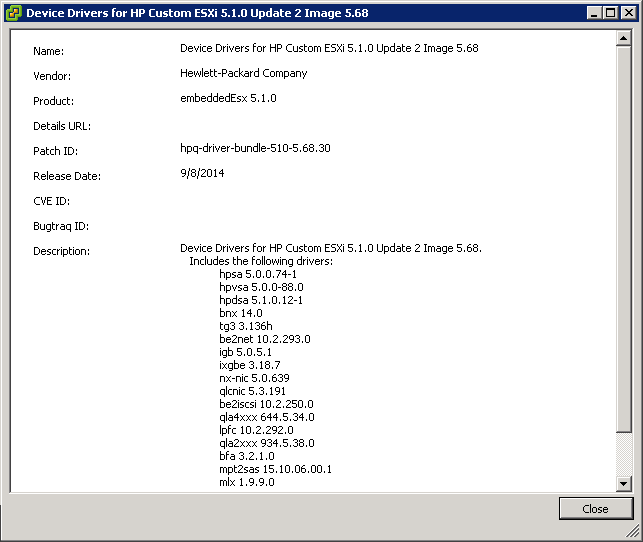

HP has introduced another batch of over 90 PowerShell cmdlets with a focus on BIOS management. The new batch of cmdlets joins two previous batches of cmdlets that allow

HP has introduced another batch of over 90 PowerShell cmdlets with a focus on BIOS management. The new batch of cmdlets joins two previous batches of cmdlets that allow